The Industrial Air Handling Unit plays a vital role in controlling air quality and regulating temperature in the manufacturing process. The air handling unit is one of the most important pieces of equipment in HVAC (heating, ventilation, and air-conditioning) systems, particularly in large-scale buildings for providing both heating and cooling for multiple zones. Air Handling Unit operations not only significantly impact supply air temperature and humidity levels, but also the energy consumed for heating, cooling, and ventilation.

What is an Air Handling Unit?

An air handling unit (AHU) is a type of equipment used to condition and circulate air as a component of a heating, ventilation, and air conditioning system. This equipment is usually constructed as a large metal box containing a blower, heating and cooling elements, filter chamber, sound attenuator, and damper. Air handlers connect to ductwork that, in turn, distributes conditioned (and heated or cooled) air throughout the building before returning it to the Air Handling Unit.

Air Handling Unit works as part of a system. It either uses a chiller with cooling water or acts as a condensing unit in a direct expansion (DX) system. As dictated by local codes and based on the application, each air handler will have different needs, including but not limited to fresh air intake, humidity control, heating, filtration, and energy recovery.

Types of air handling unit

There are basically two types of air handling units that are in use and they are the “Draw-Through” or “Blow-Through“.

In the Draw-Through type, the fan pulls the air through the mixing box, filters and cooling coil before discharging it from the fan outlet to the space to be conditioned or to the ducting network. The design can be vertical or horizontal. In this case, the section before the fan has negative pressure.

In the Blow-Through type, the fan blows the air through the mixing box, filters and cooling coil before discharging them to the conditioned space or the ducting system. In this case, the section after the fan has positive pressure.

Air Handling Units of various sizes are also available in the market. One is the terminal unit. These are small, simple units also called fan coil units or blower units. These units may include only a coil, blower and air filter. Another is the Makeup Air Unit (MAU) which is a larger Air Handling Unit that does not recirculate air and conditions 100% outside air. This unit is also known as Fresh Air Handling Unit (FAHU).

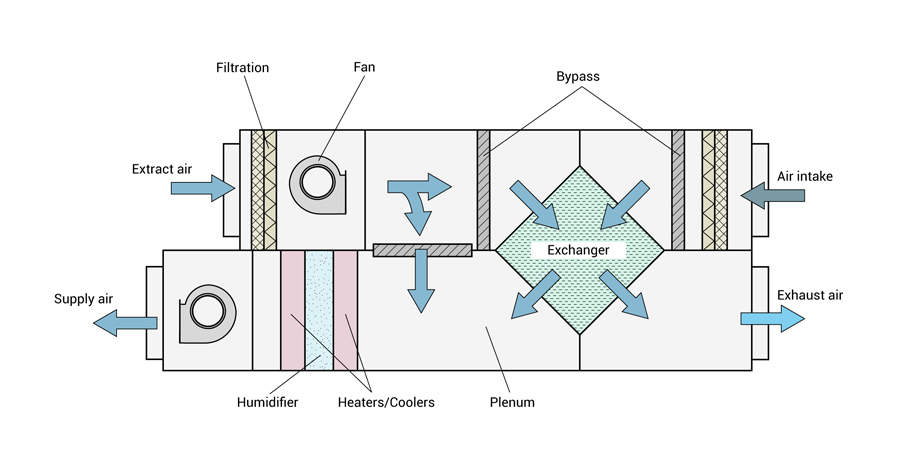

Figure: Main functions of an AHU

Main functions of an AHU

Air handling units are made up of many components, each performing a different function.

Blower: An important component of every air handling unit is the blower which performs the function of recycling the air present in the building. The air collected by the blower is conditioned (heated or cooled) and then released into the building. Air handling units at commercial buildings may have multiple blowers or fans for better functionality.

Conditioning elements: Air conditioning units use conditioning elements such as cooling coils to cool the oil in the air conditioning system. Other conditioning agents used for this include hot water, steam, and cold water.

Filters: Air handling unit filters in air conditioning units are very important for cleaning the air present in a building. The air handling unit is fitted with filters that remove dust and other unwanted material from the air to make it clean and fresh.

Humid fires: Humid fires are considered as one of the most important accessories of air handling units. They work to maintain air quality in cold climate regions. In the absence of these elements, the air can become extremely dry due to continuous heating.

Dampers: Dampers are installed inside the mixing chamber of an air handling unit and they perform another important function. This whole arrangement is used to mix air from the outside of the building and exhaust air from the inside of the building in order to condition the air more easily and quickly.

Air handling unit working process

Video Credit: AMJ Engineering

Air handling unit working process

- The working principle of the air handling unit is based on the laws of thermodynamics and fluid dynamics.

- The air handling unit is used to control and circulate air as a part of a heating, ventilating, and air-conditioning (HVAC) system. During the procedure of ventilation, natural air is provided to the space, and stale air is extricated, which is let out by means of an opening in the Air Handling Unit.

- The unit is activated by a control unit that inspects the climate control needs of the area it is servicing.

- The unit’s blower is turned on at high speed and begins to circulate the air.

- The temperature of the air is regulated by the unit’s thermostat to maintain a comfortable environment for employees.

- The filters in the unit capture particles such as pollen, dust, and bacteria that could potentially cause illness.

- The exhaust from the filters is routed through an exhaust system and released into the environment outside of the plant.

- The unit’s control unit monitors the air quality throughout the plant and makes necessary adjustments to the blower speed, thermostat settings and filters as needed.

- Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the Air Handling Unit. Small air handlers, for local use, are called terminal units, and may only include an air filter, coil, and blower.

- A larger air handler that conditions 100% outside air, and does not recirculate air, is known as a makeup air unit (MAU).

Applications area

Air handling units are useful for a number of purposes. They can be applied in a variety of locations and building types. Air Handling Units are typically located inside the building although you can also find these within rooftop plant rooms and it’s becoming more common to find robust, weather-tight, Air Handling Units sitting out in the open on the roof, to free up valuable space inside the building. These air handling units are part of a larger HVAC system that ensures that a building has proper climate control with heating and cooling along with the necessary air pressure and air quality to make employees and guests in the building comfortable and safe.

Summary

An Air Handling Unit is a much more comfortable working environment for staff and visitors. Whilst air conditioning units will either heat or cool the workspace depending on the outside temperature, an AHU will clean the air that is entering your building and even adjust the humidity. With so many new buildings becoming increasingly better insulated to reduce heat escaping, and thus reduce energy costs, the air in the building is more likely to become stale and linger for longer. So, the Air handling unit is going to be a very important accessory in business or factories in the coming days.