An Evaporator is used to facilitate the process of evaporation. It is commonly found in refrigeration and air conditioning systems, where it is used to cool air or water by absorbing heat from a liquid. The evaporator typically consists of coils or tubes that contain a refrigerant in a low-pressure state. The refrigerant evaporates and absorbs heat from the surrounding liquid, cooling it in the process. The cooled liquid can then be used to cool a building or facility. Evaporators are also used in other industries such as chemical and pharmaceutical manufacturing, desalination, and food processing.

What Is Evaporator?

An Evaporator is a key component in an air cooled chiller system. It is used to transfer heat from the chilled water being circulated through the system to the air being blown over the evaporator coils by the chiller’s fan. The evaporator coils contain a refrigerant that is in a low-pressure state, causing it to evaporate and absorb heat from the surrounding air. This process of heat transfer cools the chilled water, which is then used to cool the building or facility.

As the refrigerant evaporates, it absorbs heat from the chilled water and becomes a high-pressure vapor. The high-pressure vapor is then sent to the compressor where it is compressed and sent to the condenser where it releases the heat and turns back to low-pressure liquid refrigerant. This liquid refrigerant is then sent back to the evaporator to repeat the cycle.

Which Types evaporator is used in an air-cooled chiller?

There are several types of evaporators that can be used in an air cooled chiller system, but the most common types are

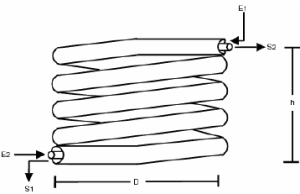

Tube-in-Tube Evaporator: This type of evaporator uses a double-walled tube design, with the refrigerant flowing through the inner tube and the chilled water flowing through the annulus (space) between the two tubes. This design allows for efficient heat transfer and is often used in smaller-capacity chiller systems.

Figure: Tube in Tube Evaporator

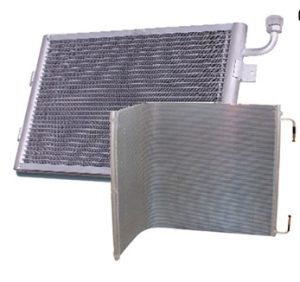

Finned-Tube Evaporator: This type of evaporator uses a series of finned tubes to increase the surface area for heat transfer. The refrigerant flows through the tubes and the chilled water flows over the fins, which transfer heat to the air being blown over the evaporator coils. This design is often used in larger-capacity chiller systems.

Figure: Tube in Tube Evaporator

Plate-and-Frame Evaporator: This type of evaporator uses a series of parallel plates to separate the refrigerant and chilled water flow. The refrigerant flows through the channels in the plates and the chilled water flows over the opposite side of the plates. The design allows for efficient heat transfer and is often used in industrial or large-scale chiller systems.

Figure: Plate and Frame Evaporator

Microchannel evaporator: This type of evaporator uses very small tubes made of aluminum or copper, the refrigerant flows through the microchannel tubes and the chilled water flows through a different set of microchannels. The design allows for efficient heat transfer with very low refrigerant charge and is often used in smaller capacity and more compact chiller systems.

Figure: Microchannel evaporator

Figure: Microchannel evaporator

The choice of evaporator type will depend on the specific requirements of the application, including the cooling capacity, system size, and cost.

Essential Function Of An Evaporator:

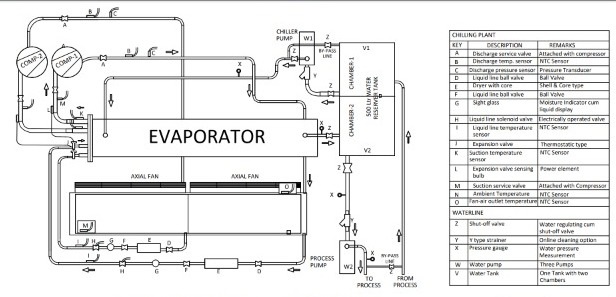

The primary function of an evaporator in an air cooled chiller system is to transfer heat from the chilled water being circulated through the system to the air being blown over the evaporator coils. The evaporator coils contain a refrigerant that is in a low-pressure state, causing it to evaporate and absorb heat from the surrounding air. This process of heat transfer cools the chilled water, which is then used to cool the building or facility.

Figure: GA Diagram Of Evaporator

Refrigerant Evaporation: The evaporator is responsible for evaporating the refrigerant, which is the first step in the refrigeration cycle. As the refrigerant evaporates, it absorbs heat from the chilled water and becomes a high pressure vapor.

Pressure Drop: The evaporator also creates a pressure drop between the inlet and outlet of the refrigerant, this is necessary for the compressor to function properly.

Dehumidification: As the warm and humid air passes over the evaporator coils, the coils absorb heat and moisture from the air, effectively dehumidifying it. This can help to improve the overall air quality and comfort in the building.

Safety: The evaporator also provides safety features to the system, by preventing liquid refrigerant from flowing into the compressor, which can cause damage and can be dangerous.

The evaporator plays a critical role in the air-cooled chiller system, as it is responsible for removing heat from the building and providing the necessary cooling to keep the building comfortable.

In summary, the chiller evaporator is a key component in an air cooled chiller system that is responsible for transferring heat from the chilled water being circulated through the system to the air being blown over the evaporator coils by the chiller’s fan. The evaporator coils contain a refrigerant that is in a low-pressure state, causing it to evaporate and absorb heat from the surrounding air. This process of heat transfer cools the chilled water, which is then used to cool the building or facility. The design and function of the evaporator play a crucial role in maintaining energy efficiency, and proper insulation is important to prevent energy loss.