Industrial machines and processes require continuous dissipation to operate efficiently, but they generate heat in large amounts. The heat is released into the environment via a heat exchange process that forms the technology of the cooling tower.

Most people believe cooling towers pollute the environment. Less than they know, it actually releases water vapor in the atmosphere. Now, with years of development and research, various cooling tower types are available with different configurations but one primary function, to dissipate heat.

The cooling towers industry has now classified cooling towers in different sizes and types to make them versatile for different applications. The article will discuss the types of cooling towers to enable you to determine which type is the right for your industry or system.

Different Cooling Tower Types

The Cooling Tower System is most commonly used in commercial, power, industrial, and HVAC industries. The industrial cooling towers are most precisely used in petroleum parts, natural gas plants, petroleum refineries, and food processing plants.

The Cooling Towers can be classified as the following:

- Air-flow generation methods

- Hybrid draft system

- Shape-categorized systems

- Atmospheric systems

- Construction-characterized systems

- Categorization as per the heat transfer method

According to the above classifications, the Cooling Tower System can be divided into three categories: Build, Heat transfer methods, and Air-flow generation methods. Let’s discuss them in detail.

Also Read: Regulate cooling tower to maximize efficiency

Build

Cooling water types are generally categorized according to the build. There are two types, Field Erection and Package.

Field Erection

The Field Erection Package is used in large power plants and manufacturing units. The specifications of this cooling tower are customizable and can be adjusted according to your industrial requirements.

Package Type

The Cooling Tower System comes with a shell made from fiberglass-reinforced polyester for high durability and heat resistance. Moreover, the materials used are corrosion-resistant as well. Due to its compact size, the type is easy to transport. You can use the package type in areas like malls, offices, and hospitals where the requirement for heat rejection is low.

Heat Transfer Methods

The Heat Transfer Methods include three types of cooling towers, closed-circuit or a fluid cooling tower, dry cooling towers, and open circuit or wet cooling towers.

Closed Circuit or Fluid Cooling Towers

The Fluid Cooling Tower includes a mixture of glycol and water as the fluid. This fluid circulates throughout the system inside the coil to dissipate heat. The tower comes with lower downtime but high productivity. It can completely remove the contamination from the surface.

Dry Cooling Towers

Dry Cooling Towers have a particular method to transfer the heat. The surface separates the working fluid from ambient air to transfer the heat. The working principle of the system uses

extended fins for the heat exchange. The air is usually introduced via the mechanical or natural draft to pass the air through ACC or air-cooled heat exchangers.

The dry cooling towers are used for power plants, factory cooling, data center cooling, plastic industry, and solar industry. Also, you can use the system in storage refrigeration systems, water-cooled chilled air conditioning systems, and cooling production equipment systems.

Open Circuit or Wet Cooling Towers

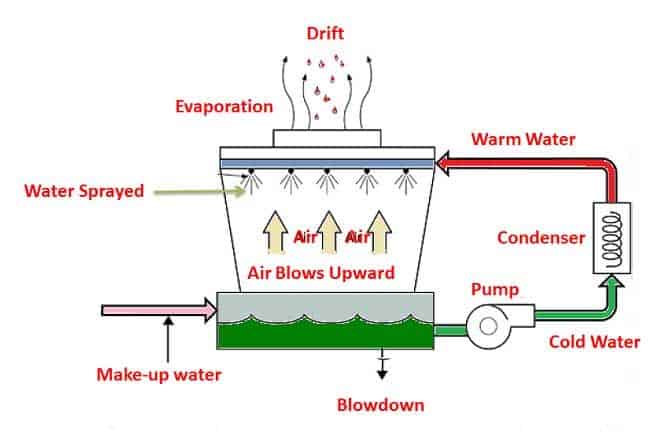

The Wet Cooling Towers are used to cool down any facility using water. The heat transfer in the tower happens when there is air moisture, an increase in wet-bulb temperature, and a decrease in process temperature.

The towers can generate drift emissions, which are not fatal. However, it includes some eliminators to reduce the effect of drift. The best part is wet cooling towers are cost-effective, affordable, and renewable.

Air-Flow Generation Methods

The last categorization of cooling water towers includes different types like cross-flow, counter-flow, mechanical draft, and natural draft cooling tower.

Natural Draft

The Natural Draft allows the air to flow naturally throughout the tower. Furthermore, the variable densities among the ambient air and warm air offer a smooth process. The moist and warm air is dense and rises in the tower, whereas the dry and cool air falls in the tower.

The process of cooling the water happens in a loop. To maintain the proper airflow, the towers are situated on the outside of any building.

Mechanical Draft

The Mechanical Draft cooling tower will require a fan to cool the flowing water in the system, which forced the air to circulate within the system. With centrifugal or propeller fans, the air keeps circulating, and the speed of the fan is controlled to regulate the capacity.

The Mechanical Draft is equipped with a smaller structure than the natural draft. However, the system is more effective and can be situated anywhere within the building with proper ventilation.

Counter-Flow

The Counter-flow cooling towers require air to enter from the bottom and move towards the top while hot water from entering from the top. Further, the water is distributed through the channel of lateral pipes.

The advantage of a Counter-Flow cooling tower is that it consumes less power, compact, and is easy to maintain.

Cross-Flow

Lastly, the Cross-Flow cooling tower requires hot water to flow vertically and air to flow horizontally. From the distribution basins, the hot water will flow. Then, the airflow will cool down the water to the required level.

The Cross-Flow cooling tower is vulnerable to freezing, making it less efficient. Also, it requires high power and more air to complete the cooling process.

Final Thoughts

The extra heat from industrial processes and machines harming the system’s efficiency can result in dire consequences. Therefore, it is essential to use a cooling tower system to remove the excess heat.

The cooling water minimizes the heat absorbed for you to save and use the same water for further processes. You have the option to choose from both large and small cooling tower types as per the requirement of your application. While there are many classifications, you are bound to choose between these two main types of cooling towers.

The small cooling towers are used for residences in which only a few liters of water are required. On the other hand, the large cooling towers can handle large quantities of water to use for industrial purposes. So, choose wisely and let your system run efficiently.