A cooling tower is an important engineering structure that ensures that buildings and industrial processes remain cool. The system uses a unique heat transfer mechanism to regulate the temperature of water and air.

Perhaps you’ve seen structures emitting condensation into the air in power facilities. Yes, these are cooling towers.

Every cooling tower in Bangladesh dissipates heat from recirculating water used to cool chillers, air conditioners, or other process equipment to the ambient air. The cooling towers dissipates heat into the environment through evaporation. Therefore, cooling towers use a lot of water, which,m if wasted, can lead to inefficiency.

Tips to Improve cooling towers efficiency in Bangladesh

Minimizing Water Loss

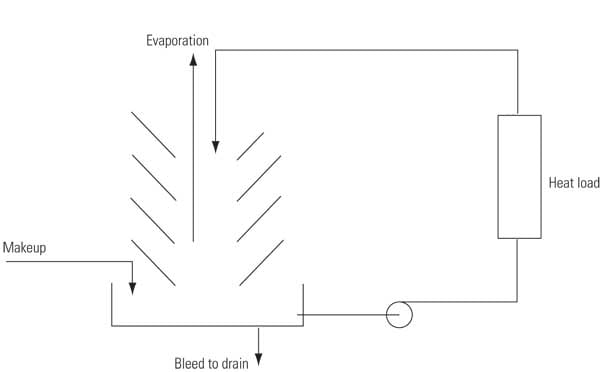

The circulation of water within a cooling tower determines how long the tower lasts and how efficient it dissipates heat. Therefore, let’s look at how water leaves the tower:

- Evaporation: This is the primary method in which heat moves from the cooling tower to the environment – the cooling tower’s primary function.

- Drift: this loss of water through droplets or mist. The amount of water is considerably smaller than evaporation and is usually with baffles and drift eliminators control the water loss.

- Blowdown: water has lost of dissolved substances like calcium, magnesium, chloride, and silica. As water evaporates, these substances remain, making water more concentrated. A very high concentration causes scale formation within the system leading to corrosion. To prevent this, replace a portion of the concentrated water with fresh make-up water. If you monitor and control the quantity of blowdown carefully, you can conserve water in your cooling tower.

- Basin leaks or overflows: always ensure there aren’t leaks by checking the float control equipment. This equipment ensures a proper basin level. Besides, ensure system valves are well tightened.

Make-up water should replace the sum of lost water:

Make-Up = Evaporation + Blowdown + Drift

Understand the Cycle of Concentration

The cycle of concentration/concentration ratio is the key parameter in evaluating cooling towers operation. Determine the value by calculating the ratio of the concentration of dissolved solids in the blowdown water compared to the make-up water.

For efficiency, maximize cycles of concentration as it will minimize blowdown water quantity and reduce make-up water demand.

An increase in the cycle of concentration causes an increase in the dissolved solids. This might cause scale and corrosion unless carefully controlled.

Typically, controlling blowdown increases efficiency.

Prevent Corrosion and Scaling Issues

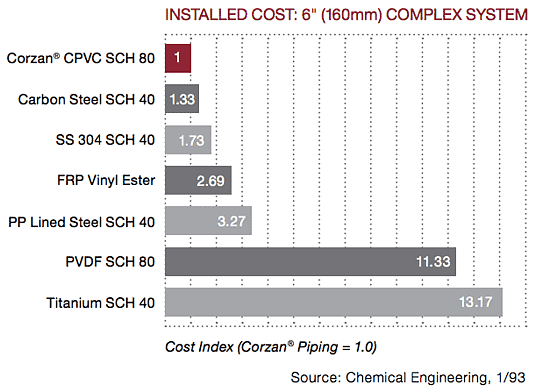

A cooling tower has corrosion and scaling issues due to the various corrosive chemical used maintenance and other processes. They include hypochlorite, caustic soda, sulfuric acid, sodium sulfite, ferrous chloride, hydrogen sulfide. These chemicals will corrode, and thus, compromise the integrity of the metallic pipes. The metallic pipe may develop it – pitting corrosion. This diminishes the thickness of the pipe walls reducing the pressure bearing capabilities.

How do you prevent scaling issues and corrosion in a cooling tower in Bangladesh?

Choose a Piping System that Increase Cooling Towers Efficiency

Always get piping material from an experienced cooling tower manufacturer in Bangladesh. These manufacturers will offer and install high-performing piping that meets an ever-increasing application demands.

Most manufacturers invest in thermoplastic pipes, which provide compelling resistance to corrosive chemicals up to 200°F (93°C) during the disinfection and maintenance processes. Besides, they provide excellent resistance to acids, bases, and salts.

Low Maintenance Piping

Metallic piping is quite complex to install as they require welding. Besides, they are inflexible –even a small adjustment can require expensive reconfigurations.

The best out of this looking for a flexible and easier to maneuver piping material – to facilitate easier installation and maintenance.

Using Alternative Water Treatment Options

Choose options that do not leave chemicals in the water. For instance, water ionization or ionizations makes water safe for cooling towers without harming piping and efficiency.

Use Retrofit Options

- Install a side-stream filtration system to filter silt and suspended solids. Besides, it returns the filtered water to the recirculating water limiting the fouling potential.

- Install a side-stream softening system when hardness is the limiting factor on the cycle of concentration

- Install automated chemical feed systems to control chemical feed based real-time chemical monitoring. These systems minimize chemical use and optimizing control against scale, corrosion, and biological growth.

Video Source: Technical Concept

Conclusion

Water efficiency affects the efficiency of cooling towers. That implies preventing water losses, maintaining the pH, and finding alternative ways of water treatment. However, a cooling tower is beyond certain measures you can opt to replace. But it is a great idea to consult a cooling towers manufacturer in Bangladesh first.