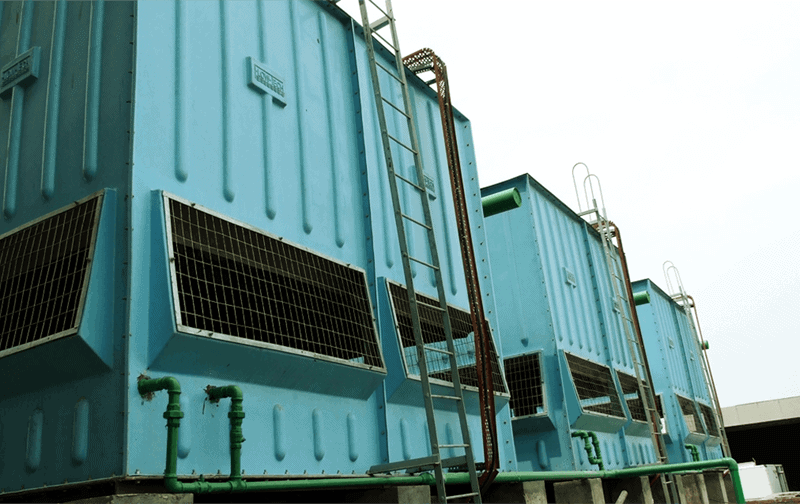

Cooling towers in industries help remove heat from different sources. The source can be a machine or any heated process material. Primarily, these cooling towers remove the heat taken up by the cooling water circulation systems used in the various industries.

It is crucial to install customizable cooling towers in the various industrial plants, including the food industry. This enables the operation of these cooling towers in plant-specific ways as the circumstances call for it. A cooling tower in the food industry performs similar functions.

Let’s take a look at the various purposes and the mechanisms of cooling towers.

The Purpose Of A Cooling Tower

A cooling tower does the job of a heat exchanger. It releases the heat into the open while returning the cold water to the chiller. The warm water for its mechanism comes from the chiller, known as the condenser water. This condenser water builds up due to the heat in the chiller.

Industries install the chiller at lower levels, similar to a basement. The associated cooling tower takes up the heated water from the chiller, cools it down before returning it to the chiller. And the process repeats.

The Working Of A Cooling Tower

The cooling tower takes up warm water from any heated process material or a heat source such as an air conditioner. The warm air scatters evenly on the top surface of the tower. While it moves down the cooling tower, the passage is exposed to a larger area for more contact with air.

Evaporation takes place in the process, which eventually takes away the heat from the water. The evaporated water then accumulates at the bottom. This cold water returns to the original source to cool, and the process repeats.

For dilution, an amount of the system water drains through a valve. The makeup line uses fresh water to replenish the cooling tower. These processes occur simultaneously in a continuous loop, making it hard to take account of all of them.

Also Read Importance of Chillers For Plastic Industry In Bangladesh

Uses Of A Cooling Tower

A cooling tower is a significant element of refrigeration systems in industrial plants. The primary use of a cooling tower being cooling the heated water of the water circulation systems; they have other associated needs to cater to. The requirements are as below:

Not only are the uses of a cooling tower in the food industry, but these towers help provide comfort cooling in various commercial buildings like an airport, school, hospital, and so on.

Industrial cooling towers help absorb the heat in the cooling water circulation systems in power plants, food industries, petroleum refineries, petrochemical plants, etc.

With the increasing demands of manufactured products worldwide, there has been a boom in the manufacturing processes. These processes generate heat which needs to be catered to for further fluent mechanism. A cooling tower is the most cost and benefits effective solution to this problem.

Cooling Towers In Food Industry

Cooling towers used in the food industry are also meant for pasteurization and sterilization arrangements. In this sector, different industries, such as the oil refineries, the sugar industry, the distilleries, wine industries, cheese, juice fruit industries, use cooling towers for smooth functionality.

The cooling towers can be customized as per the needs of a particular industry. As such, a cooling tower acts as the heat exchanger and reduces the pasteurizer water temperature. The temperature of the tower is cold enough to reduce that of the pasteurizer water temperature.

As for the sterilization processes involved in the food industry, the cooling tower acts differently than the other water disinfectants. As such, the cooling tower, in this case, helps eliminate the occurrence of pathogenic bacteria, such as Legionella bacteria. This ensures the smooth functioning of the sterilization processes.

Essential Components Of A Cooling Tower

Cooling towers in the food industry help conveniently eliminate heat. With insufficient cooling methods in the industry, there may be extensive losses in the field of food production.

Cooling towers, most importantly, act as waste heat disposers in any industrial process or a condenser for comfort cooling motives. Wet cooling towers pursue the method of evaporation through recirculating water. Here, the resultant water is vital while cooling the returning water to the process.

Cooling Tower Sizing

The size of the tower should be optimum. This is achieved by determining the four metrics of range, wet bulb temperature, heat load, and approach.

The wet-bulb temperature of the tower’s air is independent of any other factors and is a fundamental component to determine the cooling tower size. The required WBT for sizing a cooling tower is extremely hot.

In terms of the mechanical draft towers, the airflow mass determines the tower’s hot water-cooling capacity.

Efficiency Matters

The maintenance of efficiency plays a significant role in most cases as well. Cooling towers are chemically treated to avoid the growth of bacteria or contamination. Most of them compromise with the tower’s efficiency due to the effects on the metal surfaces.

Another critical factor to keep in the loop here is the footprint of these cooling towers. While the food industry opts for appointing a cooling tower for its mechanisms, it is essential to analyze it beforehand.

While a cooling tower with a smaller footprint consumes greater power, a larger cooling tower with a bigger footprint consumes lesser energy. The decision, therefore, would be a judgment call in this regard.

A cooling tower in the food industry is no different from that of other manufacturing industries. The primary purpose is to absorb the heat from the cooling water circulation systems, and it is a repetitive cycle.