Do you know how do industrial chillers work? Let’s talk about it.

Put simply, commercial buildings and residential homes will use HVAC systems to dehumidify and to cool building systems. Industries, on the other hand, will use industrial chillers to get the same effect around large manufacturing machines.

Heavy plant machinery can generate a lot of heat. This heat that occurs in hundreds of degrees cannot be normalized through the use of the regular HVACs. However, the use of chiller processors can be beneficial.

Chillers systems will facilitate the primary transfer of heat from the internal environment to the external environment. Eventually, it will help to normalize the temperatures in a given surrounding.

So how do industrial chillers work? We take you through the fundamental tips of an industrial chiller system.

How Do Industrial Chillers Work?

The first step which any type of chiller will start with is the refrigerant. The refrigerant is a chemical that holds more heat when compared to water. Due to this, the refrigerant allows for better and more efficient cooling.

The refrigerant readily changes its states from liquid to gas as it takes in heat. However, when it cools down, it again condenses back into the liquid state. By switching between the states and from the high to the low pressure, the coolant efficiently cools the air or water that’s used for this process.

In short, a chiller works by the principle of vapor absorption or just vapor compression. Chillers will provide a continuous flow of the primary coolant at the desired temperature. The chiller uses the vapor compression mechanical refrigeration technology. This technology connects to the primary process water system with the aid of a device called the evaporator.

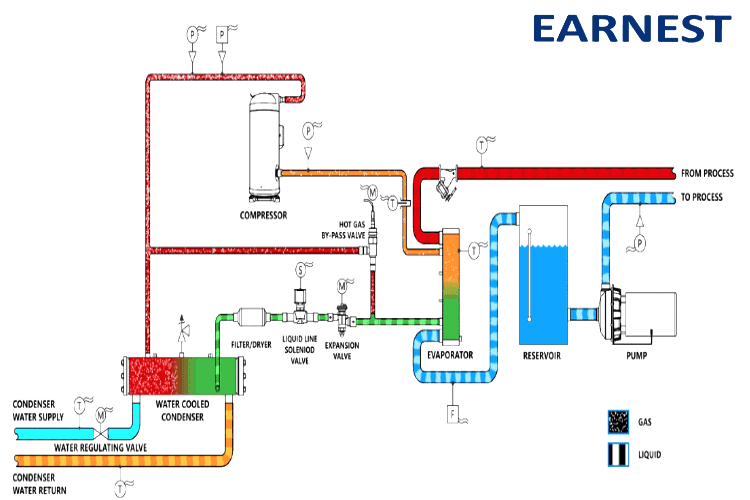

The refrigerants circulate through the evaporator, compressor, condenser, and then through the expansion device of the chiller. In each of the components, a thermodynamic process will occur, which enables the chillers to meet its goal.

When the refrigerant flows to the compressor, it performs multiple functions. Firstly, it removes the coolant from the evaporator to lower the temperature in the evaporator. This enables the evaporator to absorb heat at an ideal/correct rate.

Secondly, it raises the pressure in the outgoing refrigerant vapor and thus ensures that the temperature remains relatively high to release heat whenever it reaches the main condenser. The refrigerant then returns to the liquid state as it reaches the condenser.

At this point, the latent heat that was given up in the form of the refrigerant will change from vapor to liquid. It is this heat that’s carried away from the surrounding using the cooling medium of air or water.

Video Credit – The Engineering Mindset

Parts of a Chiller

To give you a better understanding of how an industrial chiller system works, let’s take you through the parts of a chiller system. The process chillers come with three main components, namely:

Evaporator: When the heated refrigerant picks up the heat of compression, it does so in the compressor and is then cooled in a condenser before it passes through an expansion valve, which acts as a metering device.

As this happens, it changes state to a lower temperature and low pressure. After this happens, it enters the evaporator where it starts to boil and consequently cools the process medium. The heat generated then warms the coolant and turns it into gas.

Compressor: The gas generated in the compressor is a low-pressure gas. As such, it must be raised in pressure. The compressor increases the gas pressure by physically pressing the gas. This increases the gas pressure without necessarily changing its state.

Condenser: Now, pressurized gas has to release the heat into the condenser. The air-cooled condensers will use surrounding air in removing heat from the refrigerant while the water-cooled uses the water cooling tower.

Conclusion

Remember that the evaporator always functions as the heat exchanger. This means that the heat captured by the coolant flow is transferred to the refrigerant, and as the heat-transfer is taking place, here is what happens.

The refrigerant evaporates and, in the process, changes from the low-pressure liquid and into vapor. As this happens, the temperature of the coolant reduces. This is the basic principle behind how any chiller operates.