Cooling Tower Problems and Solutions! While cooling tower serve as an essential part of industrial heating and ventilation system, they are still machines that may malfunction under multiple conditions. Sometimes these problems might occur fairly frequently. Hence, it is crucial to understand these issues in advance and find ways to fix them.

In this same regard, this article will prove to be essential in easing out operations and keeping your towers from spending days under maintenance.

What is a Cooling Tower?

Cooling towers are standard industry equipment that functions as powerful heat exchangers by providing temperature regulation. All large industrial areas have towers installed that work to keep these spaces cool and ensure the comfort of the employees. In this article we will discuss Cooling Tower Problems and Solutions.

Coolin_g towers are popularly found in industries like power plants, oil refining, steel mills, chemical processing, and other types of manufacturing outlets requiring the cooling process.

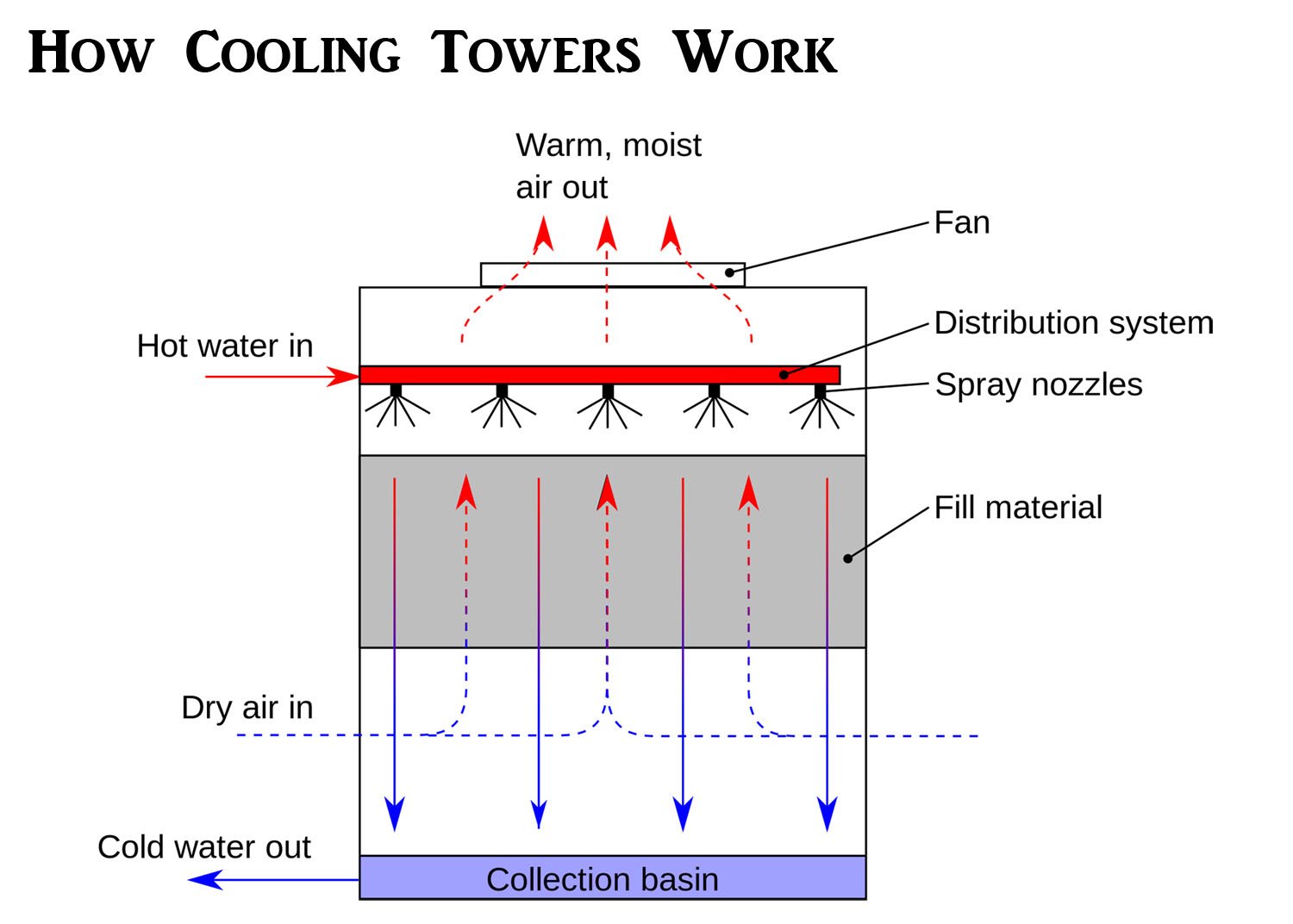

Figure – How Works?

The work on the principle of exchanging heat produced during industrial processes with cold water. Air and water are forced to be in contact to keep the process going.

The entire cooling process can be broken down into the following steps to facilitate understanding.

- The warm water is forced into the tower through pipes.

- It is then sprayed all over a heat exchange surface which maximizes air-water contact.

- The water is exposed to the air from the tower, which creates a cooling action by evaporation.

- The cooled water is collected in a basin from where it is pumped back into the processor. The process is a loop that aims at using the minimum amount of water, the maximum number of times.

May vary in design and size and are grouped based on the type of draft or the direction of air; there are square cooling towers and others. However, the function of all of them remains standard in which to exchange heat.

These are extremely efficient as they not only save water but also reduce cost and energy consumption.

It is important to know that cooling towers lose efficiency and require attention, repairs, and maintenance like every other piece of machinery.

3 Most Common Cooling Tower Problems and Solutions

Given that towers may run into problems sometimes, it is imperative to understand the nuances of the same and optimize their capacity. Additionally, understanding and resolving these problems in advance will prevent these issues from building upon one another.

Listed here are some of the most common problems that can run into with effective solutions to resolve them.

1. Biological Contamination

The insides of the towers are extremely hot and humid. It serves as a perfect breeding ground for the growth of unwanted microorganisms. These microbes include fungi and algae that form a thick slime, also referred to as biofilm, which reduces the thermal efficiency by manifolds.

This internal build-up, even in very thin layers, can harm the tower. These inefficiencies can hinder the free flow of air and water, consequently causing a breakdown of the structure.

Figure – Biological Contamination

Solution

It is imperative to understand the seriousness of the situation as these microbes can prove to be severely harmful to people’s health. They can cause several diseases, including serious respiratory problems. Collecting and testing the water sample can help identify the problem of biological contamination.

There are two ways to fix this. The first is by flushing the system with chlorine repeatedly over 48 hours, followed by a flush and refill of the tower. The second way is to inhibit the growth of microbes by the use of antimicrobial cleaners.

The idea is to eliminate all leaks to sustain the efficiency of the tower. It is critical to have experienced cooling tower suppliers treat the plant to avoid unnecessary downtime.

2. Corrosion

Repeated leakage in Cooling towers and chillers can be a consequence of persistent corrosion. This problem has been prevalent in closed loop-based systems. Air, sodium, and other chemicals corrode the metal in the tower and lead to leaks.

In any case, over a prolonged period, water can corrode anything. These chemicals aggravate the problem. Without setting up preventive measures, corrosion can take a toll on the efficiency of the cooling process while also increasing energy costs.

The problem only gets worse if the water’s pH levels become unstable. Hence, putting in place preventive measures for the same is the only way to solve corrosion.

Figure – Corrosion

Solution

One of the ways to resolve the problem of corrosion is to frequently clean towers. Additionally, industries can also use corrosion-resistant tower elements and chemicals. One of the most famous is fiber-reinforced plastic and polymeric coating solutions, which are a great way to overcome corrosion.

There are several other effective ways to cope with the problem of corrosion. These include repairing any pre-existing damage, conducting routine maintenance, and keeping up with routine checks.

3. Scaling

Simply put, scaling occurs when the concentration of dissolved liquids in the tower becomes greater than their solubility in the water. Scaling is commonly caused by chemical compounds such as calcium sulphate, calcium phosphate, and other calcium salts and materials like silica or silicates.

Like most problems, scaling also significantly decreases the efficiency of the tower. Scaling must be removed to prevent operational costs from increasing.

Figure – Scaling

Solution

Cooling Tower Problems and Solutions! As much as there are substantial scaling hazards, there are also cleaning procedures that remove the scaling.

Some commonly used methods to get rid of scaling are using coatings that allow the heat exchange to continue without providing a surface for mineral build-up. Moreover, the basic routine monitoring and cleaning of the cooling tower will prevent scaling.

Summing Up

Even though Cooling Towers are one of the most efficient and painless devices installed to improve the overall performance of the industry equipment, they can also run into problems sometimes.

We discussed some of the most common problems that you can foresee when dealing with cooling tower systems. We also discuss solutions to ensure that you have to spend minimal time and energy to ensure the device’s efficiency.