Industrial equipment, such as chillers, is a crucial element of the production process. These are commonly utilized as cooling devices in commercial and industrial establishments. Simply described, an industrial chiller is a refrigeration system that either cools or dehumidifies a fluid (water-cooled, air-cooled).

Chillers are used to quickly and effectively cool large pieces of equipment. Production rates can be maintained at an ideal level by keeping the equipment cold.

Besides maintaining the temperature of the work environment and production procedure, different types of chillers come with different functions. The most popular of them could be water or air, evaporated condensed, and many more. It is vital for the success of an industry to own a chilling plant that will fit its priorities. This article aims to provide you with a basic understanding of the variables that should be considered while purchasing an industrial chilling plant.

Why use an industrial chiller?

As an aware consumer, the purpose of purchase is something one should have no doubts about. Here are a few ways how chilling plants come to use in the manufacturing industry.

Food processing chilling plants for food processing plants

Food processing plants will benefit greatly from the use of industrial food processing chilling plants. Propylene glycol is cooled with glycol coolers that rely on the main cooling coils. Refrigerated food and beverages will be stored in these coolers. Out of all the types, water-cooled chilling plants are the best in this case. It keeps the food from going bad by maintaining a set temperature. Raw materials can also last longer thanks to them. Ice cream makers and mixers are cooled by chilling plants used by food manufacturers.

Cooling manufacturing spaces

In most manufacturing plants, several machines are installed in a specific area. Eventually, employees are exposed to danger as the workplace becomes overheated and hot. These types of heat waves can be solved by industrial chilling plants. Water-cooled chilling plants are popular for their efficiency in this job.

Plastic manufacturing

When the plastic melts, the temperature rises tremendously. In other words, when molding plastics of different shapes and sizes, it will be useful to use appropriate cooling methods. The best cooling method for this is a high-end chilling plant. Again, water-cooled chilling plants are extremely popular due to their efficiency in this task also.

Things you should look out for when buying an industrial chiller

An appropriate chilling plant will contribute immensely to the performance of an industry. That is why it is one of the most important tools to look out for when designing an industry. Below are some of the factors one should consider while purchasing an industrial chilling plant.

1. Size

Must carefully consider the size of a chilling plant before purchasing one. Proper sizing is of the utmost importance. Your equipment or materials will not be cooled properly if the chilling plant is too small. In contrast, a chilling plant that is too large will function fine but will fail prematurely over time due to its excessive capacity. Moreover, it has been overbought. But how do you figure out how big the chiller should be?

From 14,000 tons to tens of thousands of tons of capacity, industrial chilling plants are available in a variety of sizes. The following examples are representative of chilling plant sizes applied in the industry.

Medical chilling plants: A variety of 7 1 2-ton and 5-ton chillers are available for cooling multiple medical devices simultaneously, or 12 1 2-ton and 15-ton chillers for cooling multiple devices at once.

Welding chilling plants: To ensure that welders can handle 100KVA of power, we suggest having at least one ton of chilled water on hand.

Winery chilling plants: For most winery applications, a 2-ton air-cooled chilling plant is more than adequate.

Waterjet cutting chilling plants: Generally, 2-ton and 3-ton-sized waterjet cutting chilling plants are used.

Hydroponic chilling plants: The sizes of hydroponic chillers range from 1.5 tonnes to 100 tonnes.

Flower chilling plants: Range from 2-100 tons

2. Price

Depending on the model, industrial chilling plants can cost hundreds or even thousands of dollars. A water-cooled chilling plant is more expensive than an air-cooled chilling plant, as mentioned before. The designs and prices of different chilling plant manufacturers also differ, so make sure to compare prices and weigh your options before making a decision.

3. Application

For all kinds of industries, chilling plants have a variety of applications. Radiation therapy, PET scans, laboratory operations, and even blood bank refrigeration are some of the medical applications for them. In the food and beverage business, food processing chillers are used for a variety of purposes. You can choose from bakery chillers, winery glycol chillers, brewery glycol chillers, dairy milk chillers, and even commercial yogurt machine chillers, depending on your need. Metal finishing chillers, explosion-proof chillers, and cold shot chillers are also a few of the many types of chillers based on their use.

4. Equipment Manufacturer

Always familiarize yourself with the equipment manufacturer’s rules and procedures in advance. Before purchasing a chiller, consider the following questions and others:

- Is there a warranty on the chiller?

- What is the estimated turnaround time?

- How are new chillers put through their paces?

- Do they sell chiller tools and accessories?

- What is the process for preparing the chiller for shipment?

- Is it a new firm or has it been operating for a while? The longer a firm has been in operation, the more likely it is to be reputable and trustworthy.

- Is there anything unique about the chiller’s design? Because these types of parts are typically utilized to manage the chiller, that replacement part might be quite costly. These items

- become obsolete over time and are no longer supported.

- Is it easy to get in touch with a live person?

5. Types

Industrial chilling plants are classified in several ways. Let’s look at the five types of categories.

Air-Cooled chilling plants

Compared to water-cooled chilling plants, air-cooled chilling plants are often less expensive. These chilling plants, on the other hand, tend to release a lot of heat, so they’re best for places where heat isn’t a concern.

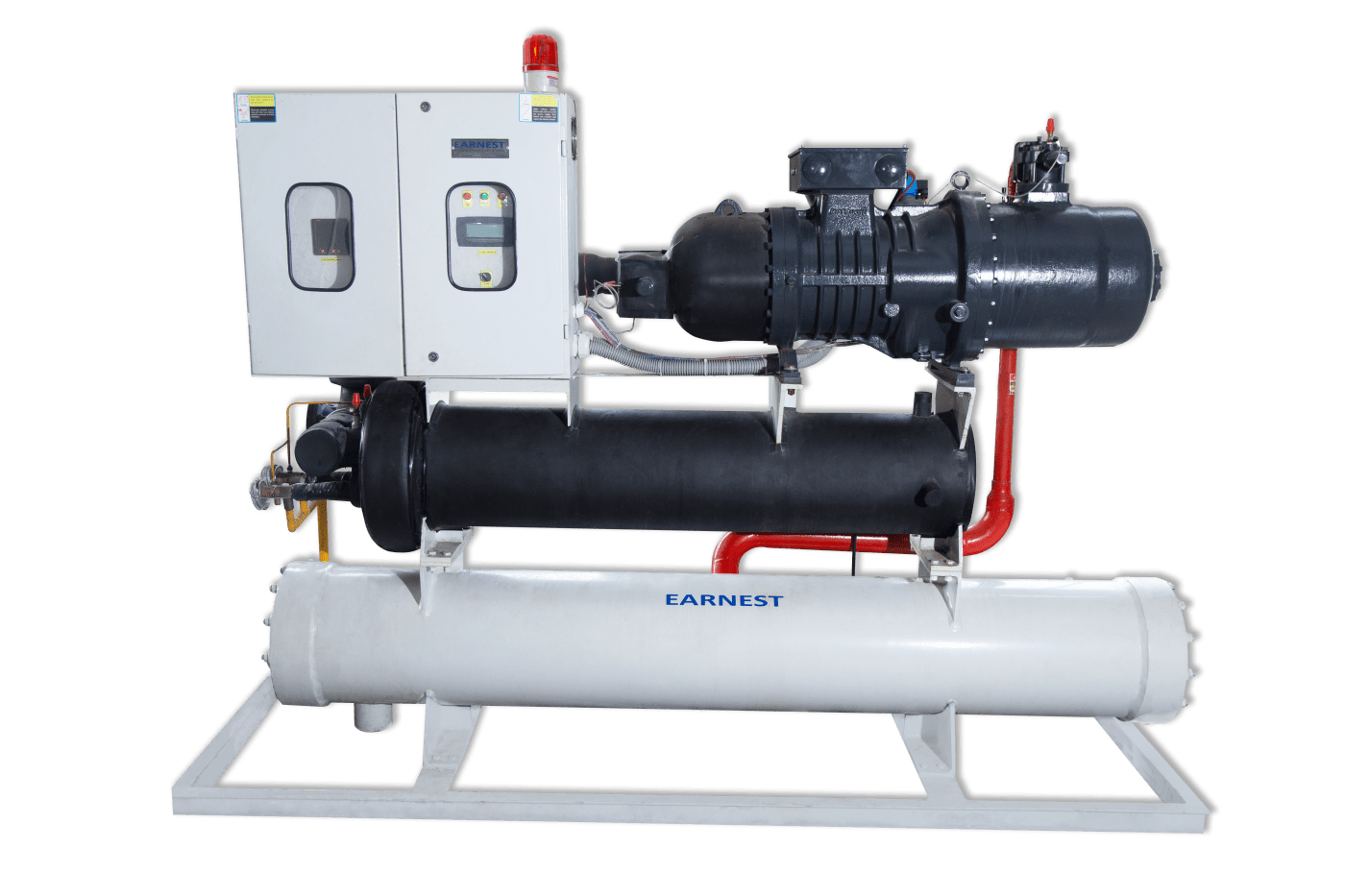

Water Cooled chilling plants

Compared to air-cooled chilling plants, water-cooled chilling plants are often quieter and more efficient. As a result, they are appropriate for both commercial and small-scale facilities.

Portable chilling plants

The term “portable” does not refer to the chiller’s mobility in this situation. A chiller, on the other hand, signifies that it comprises all of the system’s core components in a single footprint.

Stationary chilling plants

A “stationary” chiller is one that does not have a tank or a pump. Rather, they are self-contained systems that must be connected to a reservoir and pump in order to operate.

Central chilling plants

Central chillers are used to keep a variety of processes cool. They can be either portable or fixed, and they can be either air or water-cooled.

Water-cooled chilling plants are seen to be more popular in terms of covering large areas. They tend to be more sustainable and user-friendly. That is why although the price is much higher than any other type, water-cooled chilling plants are the most used currently.

Final words

The industrial rise comes with a number of successive measures. Manufacturing prerequisites are one of the key elements when it comes to gaining customer satisfaction. Therefore industrialists tend to be more careful when purchasing their tools. An effective study can assist with a firm idea of one’s priorities.